OMG FILTER PUMPS AND CLOGGING WITH ACTIVATED CARBON

In the electroplating field, the treatment with carbon is very important in polished nickel and brass platings since it reduces anomalies such as pitting, glazing, roughness...

You can proceed with two different modes:

* Cycle in continuos by using carbon filters with a high carbon and cellulose level (approx. 60%) and silicate free. Their particular compostion ensures excellent mechanical resistance to dry and wet, placing them in the range of fast filtration papers.

OMG filter pumps are designed to be able to mount carbon filters in different circular, square and rectangular sizes.

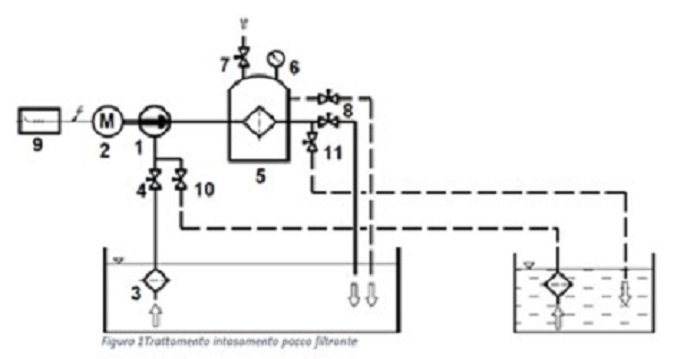

* Filtering unit clogging: the electrolyte solution is treated by depositing the coal on the filtering block with the help of an auxiliary tank.

The technology of the filtering unit allows the use of an important amount of coal, ensuring high efficiency and reducing the risk of "return" in the tank.

Experience shows that the second solution is much more effective.

FILTER PUMPS AND CLOGGING WITH ACTIVATED CARBON

To perform the clogging operation, a valve system is used, which allows to suck the solution of water and coal contained in the auxiliary tank, discharing only water. In the case of OMG filter pumps, these valves are supplied toghether with the machine.

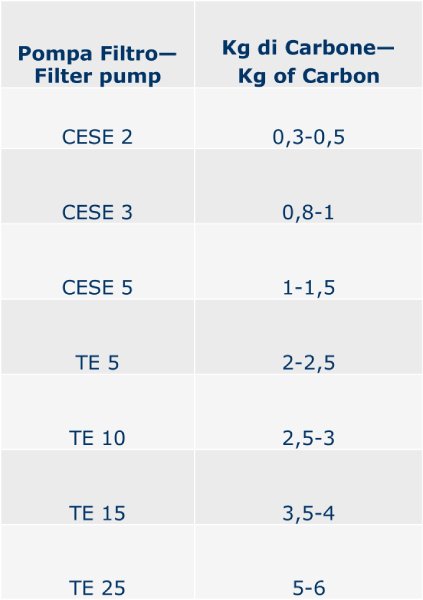

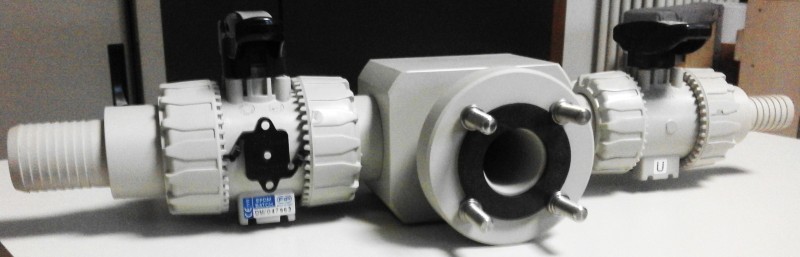

OMG filter pumps have a high holding capacity of activated carbon as showned by the table below divided into models (in the photo you can see details of unit valves mounted on the TE5 filter pump).

RULES TO BE RESPECTED IN ORDER TO OBTAIN HIGH PERFORMANCES

* One Kg of coal shoud be diluted in about 20 Lt of water;

* a galvanic bath must be filtered only once by the same coal charge;

* temperature and duration of the coal purification treatment should be well calibrated to avoid the phenomenon of the "return" in solution of what has been removed before.